What are you looking for?

Ask the NDT Man!How can we help you?

No Bull,

Just our Honest Recommendation

Let us know your requirements, and we will be happy to review and suggest the best solution. Our people are taught to offer the best value – not what makes us the most amount of money. This is a policy that has served us well for decades.

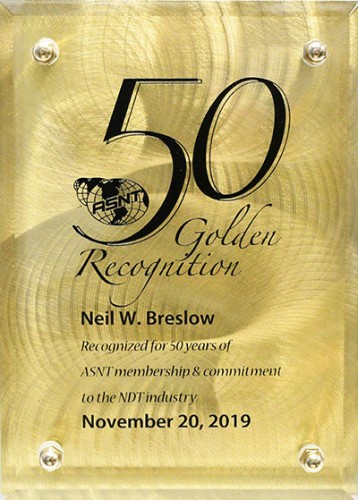

Choosing the best NDT instrument can be a challenge as there are many options to choose from. With our 50+ years of experience, we know what works, what’s "hype" and what's the best value.

The NDT Supply Difference

- Broad Assortment of Quality control Equipment

- Technical Assistance on Every Purchase

- Brand Neutral & Independent - Allowing us to be customer & application focused

- Competitive Pricing Coupled with High Standards